Product Overview

Pin Welders (pin stud welders) deliver reliable, efficient fastening for both Capacitor Discharge (CD) Stud Welding and Drawn Arc Stud Welding applications. Engineered for demanding job sites, they are the industry’s go-to solution for attaching ceramic heaters, insulation, and weld studs with accuracy and speed.

As your reliable source, KASI supplies high-quality pin welders and stud welding equipment to meet your project needs across Canada.

Pin Welders are the industry’s preferred solution for precise, reliable, and efficient fastening in stud welding applications. Designed for demanding environments, this versatile pin welder (also known as a pin stud welder) is engineered for both Capacitor Discharge Stud Welding and Drawn Arc Stud Welding processes, ensuring maximum compatibility for your job site needs.

In field heat treating applications, 99% of stud welding tasks involve capacitor discharge pin welding, using 12Ga pins to fasten flexible ceramic heaters to a variety of workpieces. Our equipment works seamlessly with 3” 12 Ga mild steel weld studs, the most commonly used fasteners in this process. For enhanced workplace safety, we recommend blunt point pins, is the new industry standard, while still accommodating regular point (sharp point) pins for those who prefer them.

When insulation attachment is required, the drawn arc stud welding process pairs perfectly with Insultwist pins to secure insulation to furnace interiors. Whether you are installing weld in studs or working with a stud welding gun to position and fasten weld studs, our stud welder ensures strong, lasting connections with minimal setup time.

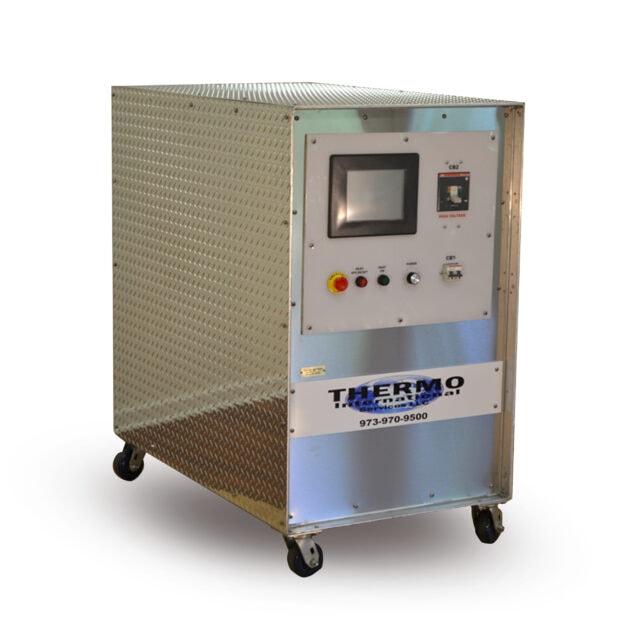

- Product Type: Capacitor Discharge Pin Welding Machine

- Model: Pinto

- Design: Lightweight, portable, and powerful

- Stud Capacity: 10 GA and 12 GA

- Power Supply: 120 V, 60 Hz

- Applications: Pin welding for insulation and fabrication projects

- Industries: Welding, fabrication, construction, oil & gas, shipbuilding

Video showcase

What types of welding processes can your pin welders handle?

Our pin welders are compatible with both Capacitor Discharge (CD) Stud Welding and Drawn Arc Stud Welding, making them versatile for a wide range of applications.

What pins are most commonly used for field heat treating applications?

In 99% of field heat treating tasks, 12 Ga pins with 3” mild steel weld studs are used to fasten flexible ceramic heaters to workpieces.

What is the difference between blunt point and sharp point pins?

Blunt point pins are the new industry standard, offering improved safety for workers, while sharp point pins remain available for users who prefer them.

Can pin welders also be used for insulation attachment?

Yes. In insulation applications, the drawn arc stud welding process with Insultwist pins is used to secure insulation to furnace interiors.

What are the main advantages of using pin welders?

Pin welders deliver precise, reliable, and efficient fastening with minimal setup time, ensuring strong and long-lasting connections in demanding environments.