Product Overview

KASI supplies pipe beveling machines and tube beveling tools for rent and sale across Canada and Alberta. Our ID-mount machines are the fastest and safest solution for field beveling and squaring of pipes and tubes, providing precision weld preparation without the risks of torching or hand grinding.

Pipe beveling involves preparing the end of a pipe or tube at a specific angle, typically before welding. With KASI’s tube beveling tools, operators can achieve:

- More accurate bevels

- Increased speed and productivity

- Improved safety (eliminating torches and hand grinders)

These tools support a wide variety of bevel types, including compound bevels, counterboring, and squaring, and are also suitable for flange facing and out-of-roundness chasers. They are not designed for pipe cutting but excel at weld preparation.

Our Protem ID mount beveling machines handle pipe diameters up to 36” OD, with electric, pneumatic, and hydraulic motor options. For maximum mobility, some smaller models are also available with battery power for use in remote job sites.

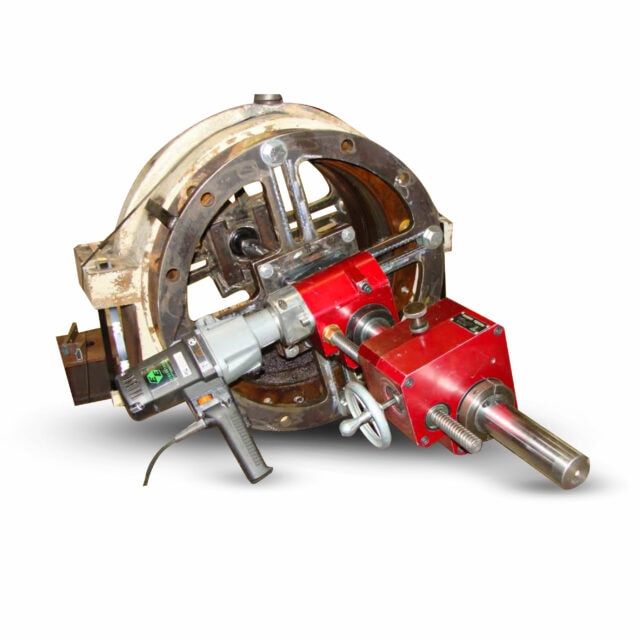

US80 Heavy-Duty Portable Beveler

The US80 portable beveling machine is designed for repeatable, high-quality weld preps on a wide range of materials, including:

- Mild steel

- Stainless steel (including duplex & super duplex)

- Chrome alloys

- Copper & copper-nickel

- Inconel and exotic alloys

- Aluminum

The US80 can be powered by pneumatic, electric, or hydraulic drive systems, and its tool bits can be adjusted or changed quickly for fast turnaround in the field.

| Technical Features | Details |

|---|---|

| Specific shapes & angles | Facing 90°, bevel 30°, 37°30, 45°, counterbore, J-bevel, other on request |

| Clamping | Manual with a key |

| Feed stroke | 60 mm (2.362″) |

| Expansion | 25 mm (0.984″) |

| Cutting head gear drive | 16 rpm off-load speed 11 rpm nominal speed. Approximate rotation speed according to air pressure and air flow |

| Single pneumatic drive | 1,47 kW, 6 bar (87 psi), 1800 l/min (63 cfm) |

| Double pneumatic drive | 2 × 1,47 kW, 6 bar (87 psi), 2 × 1800 l/min (2 × 63 cfm) |

| Electric drive | 220 V (2200 W) 110 V (1800 W) |

| Pneumatically driven machines have to be used with a lubricating filter. Recommended option: regulation valve. | |

| Order No. | Description |

|---|---|

| US80-1000 | Heavy Duty Pipe Facing Machine with dual pneumatic drive, for Ø 3.149″ – 13.976″ (80 mm – 355 mm) |

| US80-1002 | Heavy Duty Pipe Facing Machine with pneumatic drive, for Ø 3.149″ – 13.976″ (80 mm – 355 mm) |

| US80-1020 | Heavy Duty Pipe Facing Machine with electric drive 220 V, for Ø 3.149″ – 13.976″ (80 mm – 355 mm) |

| US80-1060 | Heavy Duty Pipe Facing Machine with dual hydraulic drive and regulation valve, for Ø 3.149″ – 13.976″ (80 mm – 355 mm) |

| US80-1062 | Heavy Duty Pipe Facing Machine with hydraulic drive, for Ø 3.149″ – 13.976″ (80 mm – 355 mm) |

| US80-1064 | Heavy Duty Pipe Facing Machine with single hydraulic drive and regulation valve, for Ø 3.149″ – 13.976″ (80 mm – 355 mm) |

| US80-1066 | Heavy Duty Pipe Facing Machine with single hydraulic drive, for Ø 3.149″ – 13.976″ (80 mm – 355 mm) |

| US80-1080 | Heavy Duty Pipe Facing Machine with brushless electric drive — Three-Phase Motorization — Please indicate the required voltage and frequency for your application. For Ø 3.149″ – 13.976″ (80 mm – 355 mm) |

| US80DSB-1000 | Heavy Duty Pipe Facing Machine with dual pneumatic drive, regulation valve and dual bearing (higher accuracy) for Ø 3.149″ – 13.976″ (80 mm – 355 mm) |

| US80DSB-1060 | Heavy Duty Pipe Facing Machine with dual hydraulic drive, regulation valve and dual bearing (higher accuracy) for Ø 3.149″ – 13.976″ (80 mm – 355 mm) |

What is a pipe beveling machine used for?

A pipe beveling machine is used to angle the ends of pipes or tubes to prepare them for welding, ensuring precise and repeatable weld preps.

What are the benefits of using a beveling machine instead of hand grinding?

Beveling machines provide faster, safer, and more accurate results, eliminating the risks of torching and hand grinding while increasing productivity.

What pipe sizes can your beveling machines handle?

Our ID mount tube beveling tools can handle pipe diameters up to 36” OD, covering a wide range of field applications.

What materials can the US80 beveler process?

The US80 beveling machine can process mild steel, stainless steels, duplex/super duplex, aluminum, copper, Inconel, and other exotic alloys.

Can pipe beveling machines be rented as well as purchased?

Yes. KASI offers pipe beveling machines for both rent and sale, with quick delivery and technical support across Canada and Alberta.

Can I rent, purchase or lease Pipe Beveling Machines anywhere in Canada?

Yes, KASI offers rental, sales, and leasing options for the Pipe Beveling Machines across Canada. From our locations in Sherwood Park and Fort McMurray, Alberta, we ship equipment nationwide, including British Columbia, Saskatchewan, Manitoba, Ontario, Quebec, New Brunswick, Nova Scotia, Prince Edward Island, and Newfoundland and Labrador. We also support customers across North America, with reliable delivery to industrial facilities, fabrication shops, and project sites.