Bolting

Equipment & Tools for Sale & Rental

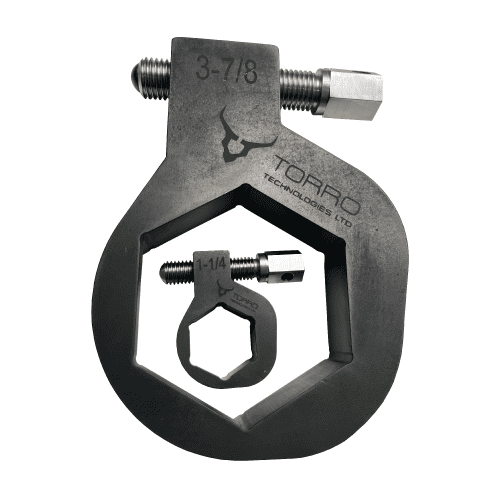

Hydraulic Bolting

Controlled hydraulic bolting requires using a specific amount of force to stretch studs, putting them in tension while clamping to other surfaces and putting them in compression. The controlled bolting applications can vary from using mechanical torque wrenches to secure the nuts on wheels for Heavy Haul Trucks to using Hydraulic Tensioners to install large heads on reactors.

The most crucial aspect in all applications is the accuracy of the applied load to the objects in tension. Hydraulic bolt tensioning offers the highest accuracy, safety, and efficiency for the entire energy industry.

Stretching Studs or Bolts can happen by 3 different methods:

1) This first method (Torquing) involves turning a nut onto the fastener. In this instance the torque applied to the nut will stretch the stud putting it into tension. Turning of the nut can be completed by a mechanical, hydraulic, Pneumatic or even battery powered tool. The amount of tension on the stud is a function of the amount of force (torque) applied to the nut, the amount a friction that the nut encounters and the fastener material.

2) The second method (Hydraulic tensioning) uses hydraulic tensioners that directly pull on the fastener to stretch it a predetermined amount, and allows for the nuts to be set in place without much force on the nut. Once the nut is secured into place the hydraulic tensioner is released, and the joint is set in compression.

3) The third method (Induction Bolting) uses heat, induced through magnetic fields, to expand faster to a predetermined length. Similar to hydraulic tensioning, the nuts get set in place without much force. Once the nut gets secured into place, the fastener begins cooling, and the joint sets in compression. For more information about hydraulic bolting, make sure to contact the Kasi Technology Inc. team today. We are happy to answer all your questions.