Product Overview

KASI is your reliable source and a trusted distributor of Plarad electric nutrunners and electric torque wrenches across Canada and North America. These tools are engineered for high-precision bolt tightening, offering electronic control, portability, and ease of use for industries requiring accuracy and repeatability.

An electric nutrunner is designed for tightening bolt joints to an exact torque, ensuring consistent and reliable fastening. Unlike pneumatic tools, which rely on compressed air, electric nutrunners use a low-inertia motor combined with a control device that electronically monitors and regulates torque.

When the desired torque level is achieved, the control system sends a pulse to brake the motor electrically, ensuring accuracy and preventing over-tightening. This makes electric torque wrenches especially suitable for assembly lines, maintenance tasks, and industries where quality assurance is critical.

Benefits of electric nutrunners include:

- Precision Control: Accurate torque delivery with electronic feedback.

- Portability: Battery or power-driven operation without compressed air.

- Clean & Quiet Operation: No exhaust air or oil mist, ideal for indoor environments.

- Ergonomic Design: Lightweight and user-friendly for extended use.

- Versatility: Widely used in automotive, aerospace, wind energy, and heavy manufacturing.

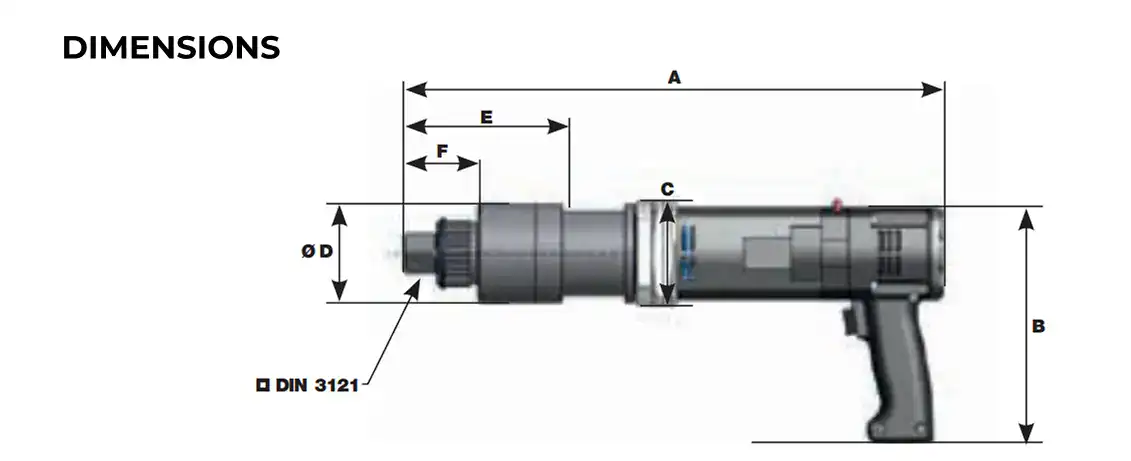

| Type | Torque range (Nm) | Speed (U/min)1 | A (mm) | B (mm) | C (mm) | Ø D (mm) | E (mm) | F (mm) | Output drive (″) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|---|

| DE1docu-10 / DE1docu-plus-10 – 110V | 150–1 000 | 16,8 | 425 | 192 | 85 | 68,5 | 145,5 | 60,5 | ¾ “ | 5,7 |

| DE1docu-10 / DE1docu-plus-10 – 230V | 150–1 000 | 19,6 | 425 | 192 | 85 | 68,5 | 145,5 | 60,5 | ¾ “ | 5,7 |

| DE1docu-20 / DE1docu-plus-20 – 110V | 250–2 000 | 9,0 | 449 | 192 | 85 | 80 | 132 | 61,5 | 1 “ | 6,8 |

| DE1docu-20 / DE1docu-plus-20 – 230V | 250–2 000 | 12,0 | 449 | 192 | 85 | 80 | 132 | 61,5 | 1 “ | 6,8 |

| DE1docu-30 / DE1docu-plus-30 – 110V | 450–3 000 | 5,9 | 465 | 192 | 85 | 80 | 132 | 61,5 | 1 “ | 7,2 |

| DE1docu-30 / DE1docu-plus-30 – 230V | 450–3 000 | 8,0 | 449 | 192 | 85 | 80 | 132 | 61,5 | 1 “ | 7,2 |

| DE1docu-36 / DE1docu-plus-36 – 110V | 500–3 600 | 4,5 | 465 | 192 | 85 | 80 | 132 | 61,5 | 1 “ | 7,2 |

| DE1docu-36 / DE1docu-plus-36 – 230V | 500–3 600 | 5,2 | 465 | 192 | 85 | 80 | 132 | 61,5 | 1 “ | 7,2 |

| DE1docu-48 / DE1docu-plus-48 – 110V | 700–4 800 | 3,5 | 497 | 192 | 85 | 86 | 161 | 83,5 | 1 ½ “ | 9,0 |

| DE1docu-48 / DE1docu-plus-48 – 230V | 700–4 800 | 4,6 | 497 | 192 | 85 | 86 | 161 | 83,5 | 1 ½ “ | 9,0 |

| DE1docu-80 / DE1docu-plus-80 – 110V | 1 200–8 000 | 2,0 | 565 | 192 | 75 | 101 | 211,5 | 106 | 1 ½ “ | 14,5 |

| DE1docu-80 / DE1docu-plus-80 – 230V | 1 200–8 000 | 2,5 | 565 | 192 | 75 | 101 | 211,5 | 106 | 1 ½ “ | 14,5 |

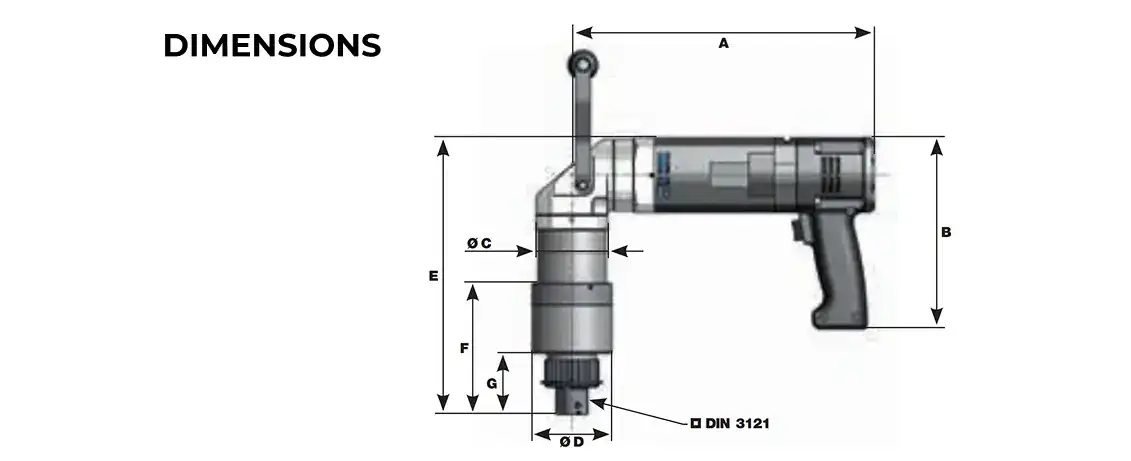

| Type | Torque range (Nm) | Speed (U/min)1 | A (mm) | B (mm) | C (mm) | Ø D (mm) | E (mm) | F (mm) | G (mm) | Output (″) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| DE1docu-10-W / DE1docu-plus-10-W – 110V | 150–1 000 | 16,8 | 303 | 192 | 72 | 68,5 | 253 | 145,5 | 60,5 | ¾ “ | 7,1 |

| DE1docu-10-W / DE1docu-plus-10-W – 230V | 150–1 000 | 16,8 | 303 | 192 | 72 | 68,5 | 253 | 145,5 | 60,5 | ¾ “ | 7,1 |

| DE1docu-20-W / DE1docu-plus-20-W – 110V | 250–2 000 | 9,0 | 303 | 192 | 72 | 80 | 277,5 | 132 | 61,5 | 1 “ | 8,3 |

| DE1docu-20-W / DE1docu-plus-20-W – 230V | 250–2 000 | 9,0 | 303 | 192 | 72 | 80 | 277,5 | 132 | 61,5 | 1 “ | 8,3 |

| DE1docu-30-W / DE1docu-plus-30-W – 110V | 450–3 000 | 5,9 | 303 | 192 | 72 | 80 | 293,5 | 132 | 61,5 | 1 “ | 8,6 |

| DE1docu-30-W / DE1docu-plus-30-W – 230V | 450–3 000 | 5,9 | 303 | 192 | 72 | 80 | 293,5 | 132 | 61,5 | 1 “ | 8,6 |

| DE1docu-36-W / DE1docu-plus-36-W – 110V | 500–3 600 | 4,5 | 303 | 192 | 72 | 80 | 293,5 | 132 | 61,5 | 1 “ | 8,6 |

| DE1docu-36-W / DE1docu-plus-36-W – 230V | 500–3 600 | 4,5 | 303 | 192 | 72 | 80 | 293,5 | 132 | 61,5 | 1 “ | 8,6 |

| DE1docu-48-W / DE1docu-plus-48-W – 110V | 700–4 800 | 3,5 | 303 | 192 | 72 | 86 | 326 | 161 | 83,5 | 1 ½ “ | 9,2 |

| DE1docu-48-W / DE1docu-plus-48-W – 230V | 700–4 800 | 3,5 | 303 | 192 | 72 | 86 | 326 | 161 | 83,5 | 1 ½ “ | 9,2 |

| DE1docu-80-W / DE1docu-plus-80-W – 110V2 | 1 200–8 000 | 2,0 | 303 | 192 | 72 | 101 | 393 | 211,5 | 106 | 1 ½ “ | 17,0 |

| DE1docu-80-W / DE1docu-plus-80-W – 230V2 | 1 200–8 000 | 2,5 | 303 | 192 | 72 | 101 | 393 | 211,5 | 106 | 1 ½ “ | 17,0 |

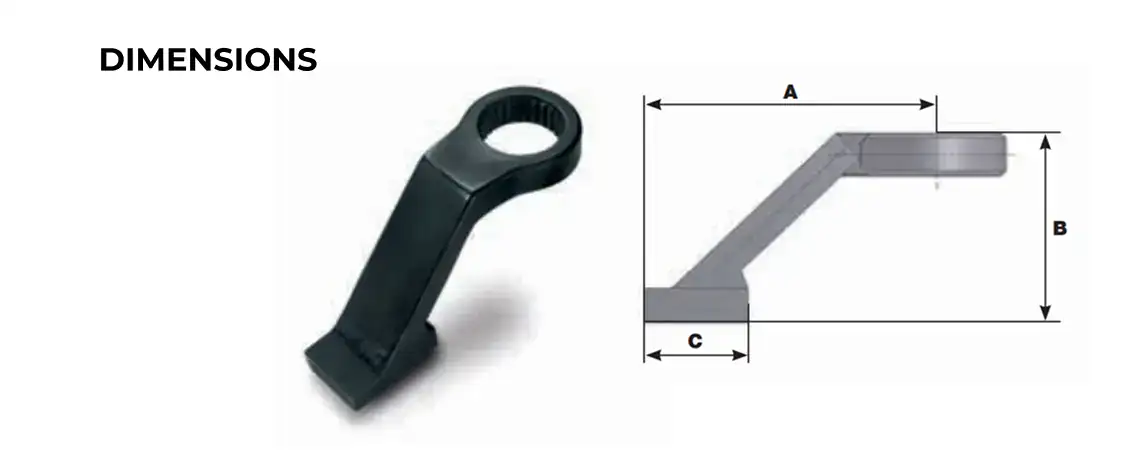

| Type | A (mm) | B (mm) | C (mm) | Weight (kg) |

|---|---|---|---|---|

| DE1docu-10 | 150 | 100 | 90 | 1,5 |

| DE1docu-20 | 150 | 100 | 90 | 1,85 |

| DE1docu-30 | 190 | 100 | 90 | 2,4 |

| DE1docu-36 | 190 | 100 | 90 | 2,4 |

| DE1docu-48 | 210 | 130 | 90 | 3,25 |

| DE1docu-80 | 250 | 165 | 140 | 7,38 |

What is an electric nutrunner?

An electric nutrunner is a precision torque tool used to tighten bolt joints to an exact torque value. It combines a low-inertia motor with a control device that electronically monitors and terminates the tightening process at the correct level.

What are the advantages of electric torque wrenches?

Electric torque wrenches are portable, precise, and clean to operate, making them ideal for assembly environments and industries where mobility and accuracy are critical.

Which industries use electric nutrunners?

Industries such as automotive, aerospace, oil & gas, wind energy, and heavy manufacturing rely on electric nutrunners for fast, accurate, and repeatable bolting.

How do electric torque wrenches ensure accuracy?

The built-in control system monitors torque output. Once the desired tightening torque is achieved, the system sends a pulse to brake the motor electrically, preventing over-tightening.

What is the difference between electric and pneumatic torque wrenches?

Electric torque wrenches are portable and convenient, offering clean operation and precise torque control without the need for compressed air. In comparison, pneumatic torque wrenches use compressed air to deliver high, continuous torque, making them better suited for heavy-duty, repetitive tasks in demanding industrial environments.