Product Overview

KASI supplies high-quality nut splitters across Canada and Alberta, offering a safe, effective solution for removing corroded, rusted, or over-tightened nuts without the need for hot work. Built for reliability, our hydraulic nut splitters provide a cold-cut alternative that improves safety and efficiency in maintenance and repair operations.

Our nut splitters are designed to quickly and safely split corroded nuts up to RC44 hardness. They are especially valuable in industries where safety regulations prohibit open flames or “hot work” permits. By applying hydraulic force, the nut splitter creates a clean break in the nut, allowing it to be removed without damaging the stud or bolt.

These tools are ideal for environments such as refineries, power plants, shipyards, mining, and heavy manufacturing where fastener removal is often a challenge.

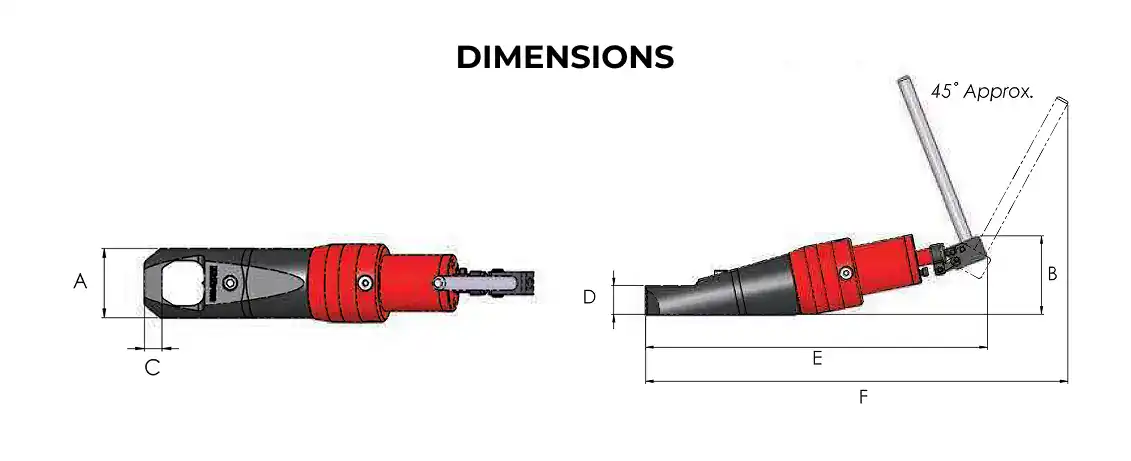

SELF CONTAINED NUT SPLITTER

| Model number | Capacity (tons) | Hexagon AF sizes (inch) | Hexagon AF sizes (mm) | Stud bolt thread sizes (imperial) | Stud bolt thread sizes (metric) | Weight (lbs) | Dimensions (in) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | |||||||

| HMNS104 | 18 | 11/16″ – 1 1/4″ | 17 – 32 | 1/2″ – 3/4″ | M10 – M22 | 12.8 | 2.52 | 3.47 | 0.49 | 1.18 | 14.97 | 17.93 |

| HMNS110 | 27.4 | 1 1/4″ – 1 5/8″ | 32 – 41 | 3/4″ – 1″ | M22 – M27 | 17.4 | 3.07 | 3.98 | 0.79 | 1.46 | 17.34 | 21.28 |

| HMNS200 | 45.4 | 1 5/8″ – 2″ | 41 – 50 | 1″ – 1 1/4″ | M27 – M33 | 30.0 | 3.7 | 4.41 | 0.83 | 1.69 | 18.56 | 22.3 |

| Blade part number | For nut splitter |

|---|---|

| NS104-B | HMNS104 |

| NS110-B | HMNS110 |

| NS200-B | HMNS200 |

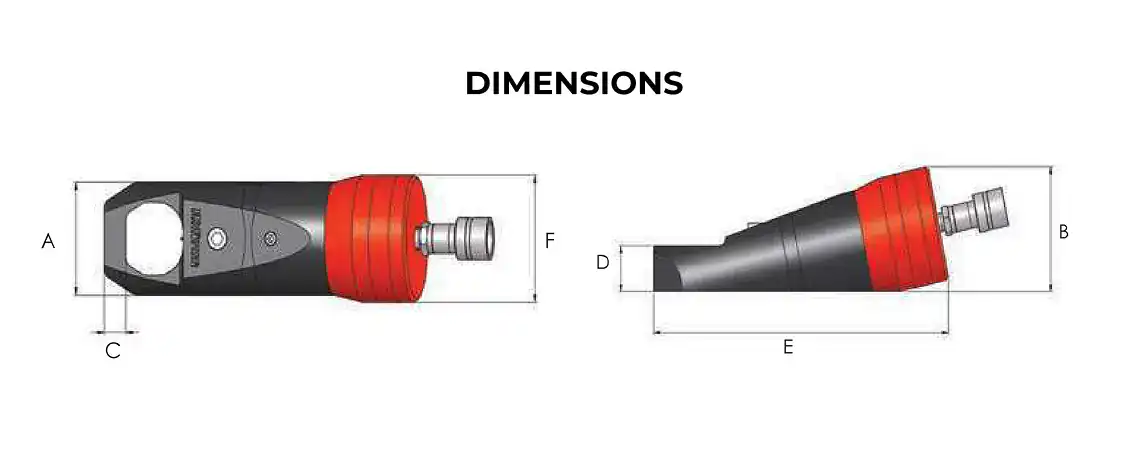

SINGLE ACTING NUT SPLITTER

| Model number | Capacity (tons) | Oil capacity (in³) | Hexagon AF sizes (inch) | Hexagon AF sizes (mm) | Stud bolt thread sizes (imperial) | Stud bolt thread sizes (metric) | Weight (lbs) | Dimensions (in) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | ||||||||

| NS104 | 18 | 18 | 11/16″ – 1 1/4″ | 17 – 32 | 1/2″ – 3/4″ | M10 – M22 | 8.8 | 2.52 | 3.03 | 0.49 | 1.18 | 8.27 | 2.64 |

| NS110 | 27.4 | 27.4 | 1 1/4″ – 1 5/8″ | 32 – 41 | 3/4″ – 1″ | M22 – M27 | 16.3 | 3.07 | 3.78 | 0.79 | 1.46 | 11.27 | 2.68 |

| NS200 | 45.4 | 45.4 | 1 5/8″ – 2″ | 41 – 50 | 1″ – 1 1/4″ | M27 – M33 | 23.4 | 3.78 | 4.57 | 0.83 | 1.69 | 12.41 | 4.26 |

| NS206 | 63.7 | 63.7 | 2″ – 2 3/8″ | 50 – 60 | 1 1/4″ – 1 1/2″ | M33 – M39 | 34.8 | 4.53 | 5.44 | 0.95 | 2.05 | 13.24 | 4.96 |

| NS215 | 99.6 | 99.6 | 2 3/8″ – 2 15/16″ | 60 – 75 | 1 1/2″ – 1 7/8″ | M39 – M48 | 86.6 | 6.15 | 6.9 | 1.06 | 2.96 | 16.78 | 6.38 |

| Blade part number | For nut splitter |

|---|---|

| NS104-B | NS104 |

| NS110-B | NS110 |

| NS200-B | NS200 |

| NS206-B | NS206 |

| NS215-B | NS215 |

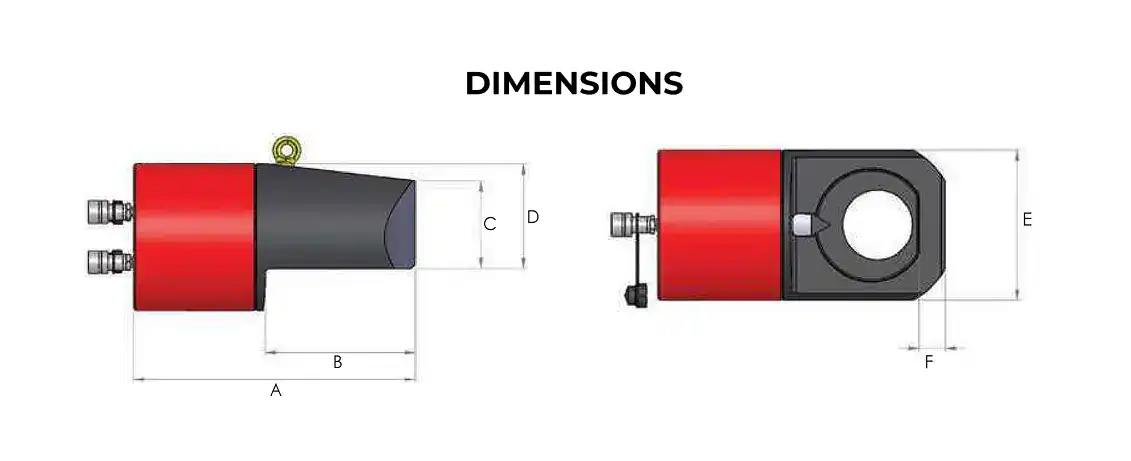

DOUBLE ACTING NUT SPLITTER

| Model number | Capacity (tons) | Oil capacity (in³) | Hexagon AF sizes (inch) | Hexagon AF sizes (mm) | Stud bolt thread sizes (imperial) | Stud bolt thread sizes (metric) | Weight (lbs) | Dimensions (in) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | ||||||||

| DNS404 | 131.8 | 48.56 | 2 15/16″ – 4 1/4″ | 75 – 105 | 1 7/8″ – 2 3/4″ | M48 – M72 | 110.2 | 14.95 | 7.56 | 3.92 | 5.14 | 7.21 | 1.34 |

| DNS506 | 224.2 | 92.11 | 4 1/4″ – 5 3/8″ | 105 – 136 | 2 3/4″ – 3 1/2″ | M72 – M95 | 211.6 | 17.77 | 9.46 | 5.52 | 6.6 | 9.26 | 1.62 |

| Blade part number | For nut splitter |

|---|---|

| DNS404-B | DNS404 |

| DNS506-B | DNS506 |

How to use a nut splitter?

To use a nut splitter, place the tool over the corroded or seized nut, align the cutting blade with the flat surface of the nut, and apply hydraulic force. The splitter drives into the nut, creating a clean break so it can be safely removed.

Do nut splitters damage the bolt?

No. Nut splitters are designed to cut through the nut only. The bolt or stud remains undamaged, allowing it to be reused in most cases once the nut has been removed.

What is the correct way to use a hydraulic nut splitter?

Hydraulic nut splitters should always be positioned squarely on the nut, with the blade aligned on one of the nut’s flats. Once activated, the hydraulic system applies steady pressure until the nut cracks open.

When should you use a nut splitter?

A nut splitter should be used when nuts are too corroded, rusted, over-tightened, or frozen in place to be removed with conventional tools. They are especially valuable in industries where “hot work” (cutting with torches or grinders) is not permitted.

What types of industries benefit from nut splitters?

Nut splitters are widely used in oil & gas, petrochemical, mining, power generation, and heavy manufacturing,, industries where safe and efficient fastener removal is essential.