Field Machining

The practice of Field Machining is a great way to provide machine shop finishes to parts and work pieces insitu, without the cost and time delays of shipping. Usually applied to larger work pieces that are impractical to transport to a machine shop.

From giving a large diameter heavy wall pipe a compound 37-10 bevel with a 1/8th inch land, to line boring a 80 Ton Dipper Bucket to accept bushings for pivot pins. The applications requiring field machining are wide spread.

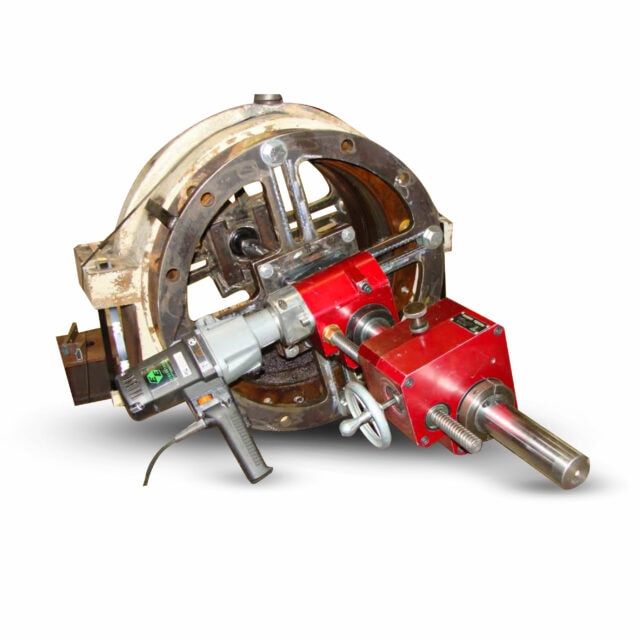

Equipment Selection is critical to ensure a timely and high quality finish.

Why is there a need for flange facing machines?

When flanges are deformed due to flows inside a network (water, steam, oil & gas, etc.) and even damaged from outside due to vibrations or bad handlings a flange-facing machine is needed. The quality of a flange facing is fundamental because sealing and pressure resistance depends on it.