Product Overview

As an authorized Plarad distributor in North America, KASI provides high-quality pneumatic nutrunners designed for efficient torque application with minimal operator effort. Based in Edmonton, Alberta, we deliver and support pneumatic and air-driven torque tools across Canada and the U.S., serving industries such as oil & gas, power generation, aerospace, and heavy manufacturing.

A pneumatic nutrunner is a planetary torque multiplier, combining a precision gearbox with a pneumatic air motor. The gearbox amplifies torque while the integrated reaction device absorbs counter-forces, ensuring the operator can apply powerful torque with very little physical effort.

Plarad’s air nutrunners are widely recognized for their durability, reliability, and ergonomic operation. With a lightweight build and advanced torque multiplication technology, they are suitable for critical bolting applications where accuracy and repeatability are essential.

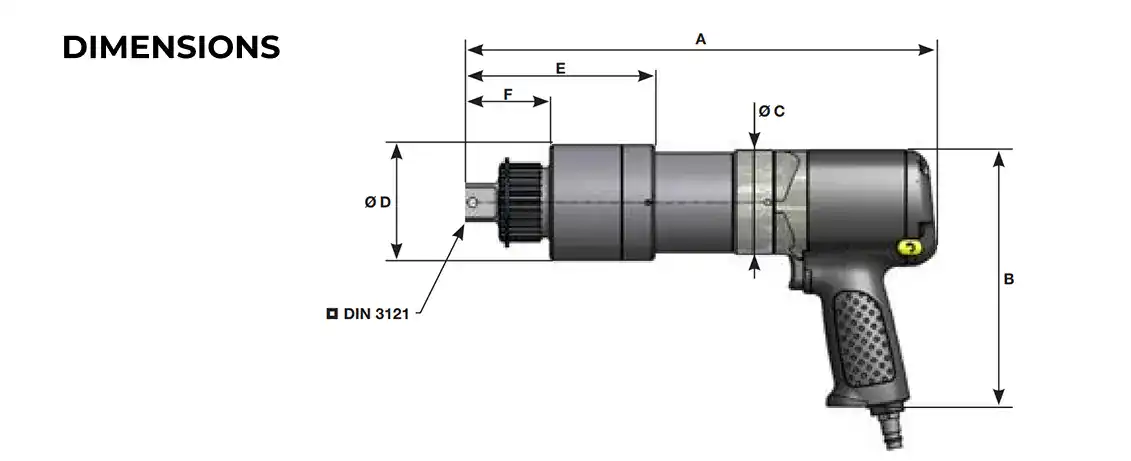

| Type | Pressure p (bar) | Torque range (Nm) | Speed n (rpm)* | A (mm) | B (mm) | C (mm) | Ø D (mm) | E (mm) | F (mm) | Output drive (″) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| DP1-05 | 6 | 125 – 500 | 55 | 281 | 177 | 72 | 68.5 | 144.5 | 60.5 | ¾ “ | 4.7 |

| DP1-10 | 6 | 250 – 1,000 | 27.5 | 297 | 177 | 72 | 68.5 | 144.5 | 60.5 | ¾ “ | 4.9 |

| DP1-20 | 6 | 380 – 2,000 | 7.2 | 321 | 177 | 72 | 80 | 132 | 61.5 | 1 “ | 6.0 |

| DP1-30 | 6 | 580 – 3,000 | 4.2 | 337 | 177 | 72 | 80 | 132 | 61.5 | 1 “ | 6.6 |

| DP1-36 | 6 | 760 – 3,600 | 3.6 | 337 | 177 | 72 | 80 | 132 | 61.5 | 1 “ | 6.6 |

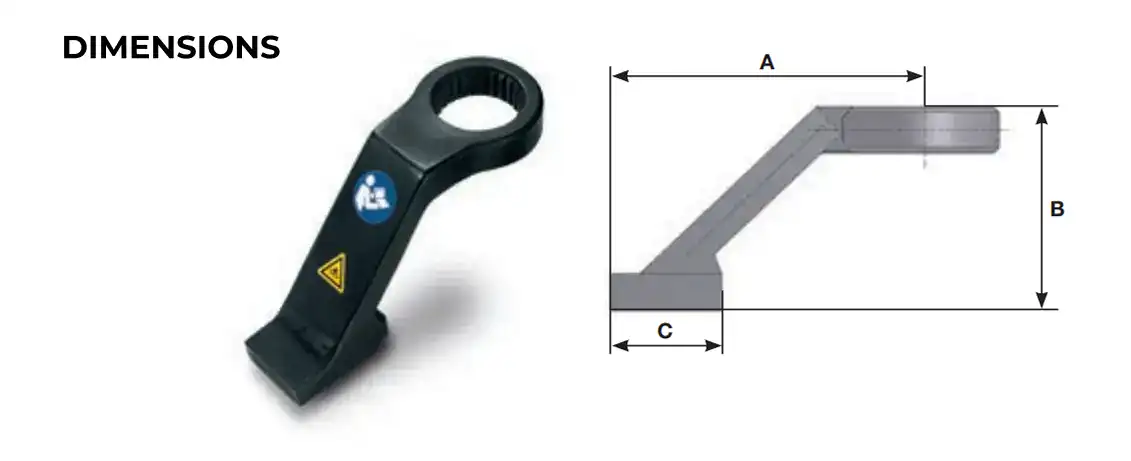

| Type | A (mm) | B (mm) | C (mm) | Weight (kg) |

|---|---|---|---|---|

| DP1-05 | 184 | 100 | 90 | 1,5 |

| DP1-10 | 184 | 100 | 90 | 1,5 |

| DP1-20 | 190 | 100 | 90 | 1,85 |

| DP1-30 | 230 | 110 | 90 | 2,4 |

| DP1-36 | 230 | 110 | 90 | 2,5 |

What is a pneumatic nutrunner?

A pneumatic nutrunner is a planetary torque multiplier that uses a pneumatic air motor and gearbox to apply high torque with minimal operator effort.

How does a pneumatic nutrunner work?

The air motor powers the gearbox, which multiplies torque. A built-in reaction device absorbs opposing torque, allowing safe and efficient tightening.

What are the benefits of using a pneumatic nutrunner over manual tools?

They reduce operator strain, improve torque accuracy, and speed up bolting operations compared to manual torque multipliers or wrenches.

Which industries use pneumatic nutrunners?

Common industries include oil & gas, wind energy, aerospace, automotive, shipbuilding, mining, and heavy manufacturing.

What is the difference between pneumatic and electric nutrunners?

Pneumatic nutrunners use compressed air to deliver high, continuous torque, making them ideal for heavy-duty, repetitive tasks in industries like oil & gas and manufacturing. In comparison, electric nutrunners are portable and convenient, suitable for a variety of applications, but they require batteries or a power connection for operation.