Field Heat Treatment

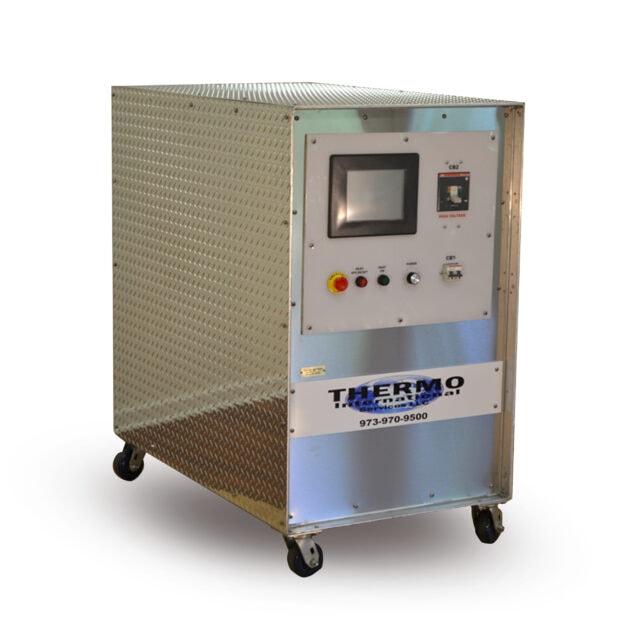

Equipment & Tools for Sale & Rental

Local Heat Treating

Field Heat Treating takes on many forms in terms of its application to materials, commonly referred to as Cooperheat or Cooperheating. It is defined as the in-field application of heat, to materials to intentionally alter their properties. The property changes can be physical and/or mechanical.

Cooperheat has been the industry pioneer and has subsequently become the generic and most recognizable name. Recently, Cooperheat Equipment Ltd. acquired Stork UK’s Cooperheat Manufacturing Division, and the company now holds the license to use the Cooperheat brand in the UK, USA, and Canada.

As KASI, we take pride in our integral role within the distribution network across North America. Our commitment also extends to providing comprehensive repair and maintenance services for Cooperheat equipment.

Benefits of Heat Treating

Heat treating can offer various benefits, including weld strength, corrosion resistance, material durability, and material resilience. Additionally, preheating your materials before a weld can help avoid material stresses, slow the rate at which it cools, as well as prevent shrinkage and hydrogen cracking along the heat-affected zone. A post-heat treatment helps diffuse any remaining hydrogen and lowers the chances of hydrogen-induced cold cracking. Regardless of the reasons for utilizing heat treatment, the advantages are practically endless. Below, we’ve listed some of the most common uses for Local heat treating.

The most common applications of Field Heat Treatment are:

- Welding Pre-Heat

- Post Weld Heat Treatment (PWHT) / Stress Relieving

- Sweat Fitting / Interference Fitting /Hub Removal

- De-Gassing / Bake-Out / Dehydrogenation (DHT)

- Solution Annealing

- Refractory / Coating Curing

- Refractory Drying

- Process Start-Ups / Warm-Ups

- Bolt / Stud / Nut Removal

- Line Thaws

The following equipment is often used to perform the above-mentioned applications:

- Electrical Resistance (Cooperheat)

- High Velocity Combustion

- Induction

- Furnaces

- Pin Welding

- Insulating Materials

- To learn more about Local heat treating and its various industrial applications, contact the KASI team today.