Gas/Valve Train

A Gas / Valvetrain is an assembly of piping, control and safety valves, and a flame safety system that is needed to safely control the pressure and flow rates of fuel to the High-Velocity Burner and monitor flame safety. Per the National Fire Protection Association (NFPA) and the American and Canadian Gas Association guidelines.

Safety-interlocked pressure, flow, and flame control components ensure that the system operates safely and feedback to the Combustion Technician during equipment start-up and operation.

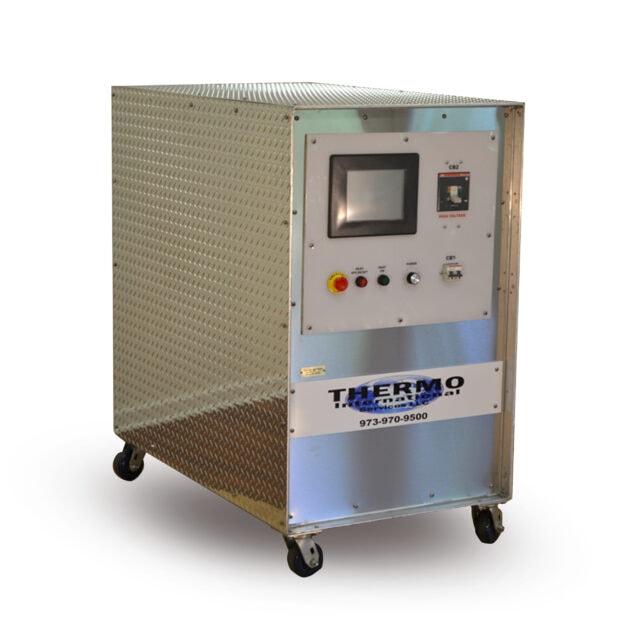

Portable gas trains are in wheeled cabinets and available in various sizes and BTU capacities. An automatic gas train utilizes a closed-loop microprocessor temperature controller. In contrast, a manual gas train requires operator interaction. It is best suited for such thermal processes as refractory dry-outs and furnace stress reliefs, where an array of thermocouples is needed to affirm temperature uniformity.